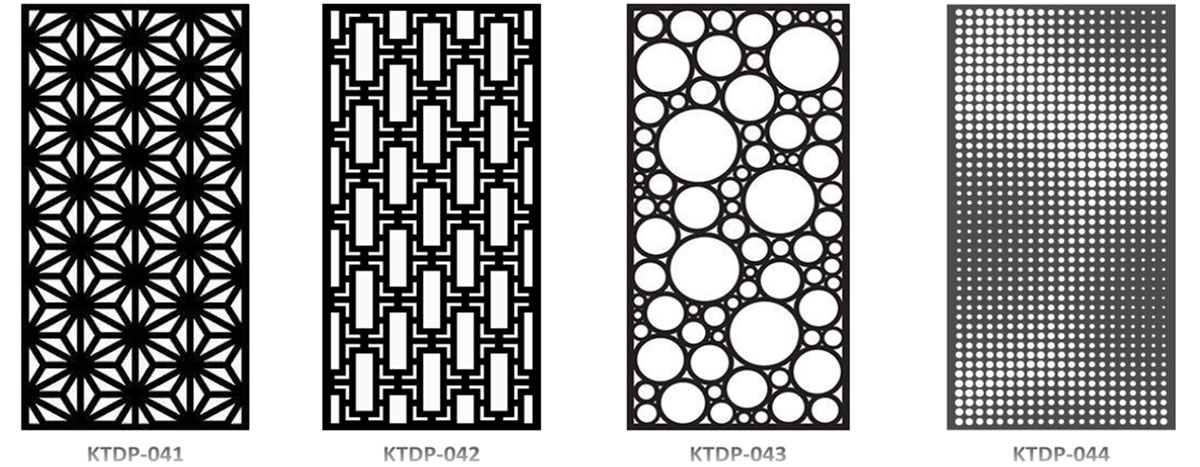

Turret Punching Perforated Metal Panel for decoration

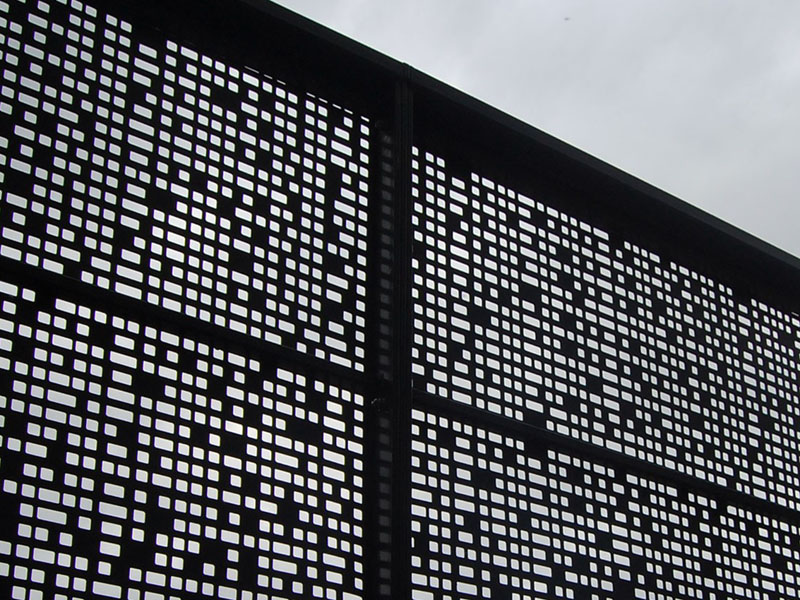

Turret punching is a method of adding a decorative element to sheet metal. The press punches uniform holes through a sheet of metal, creating patterns and textures. Turret punching is fast and versatile, and the hole designs can be round, diamond shaped, triangle, square and more. From standard perforated sheets to detailed decorative metal, turret punching can truly turn your building into a work of art.

Why choose Turret Punching Perforated Metal?

Sheet Master: Automated loading and unloading

Sheet Master: Automated loading and unloading

Grip Master: Removal of sheet skeletons

Grip Master: Removal of sheet skeletons

Sort Master pallet: Part pick & sort blanks

Sort Master pallet: Part pick & sort blanks

Sheet capacity of 3048mm by 1524mm

Sheet capacity of 3048mm by 1524mm

Cheaper than Laser Cutting perforated sheet

Cheaper than Laser Cutting perforated sheet

SPECIFICATION

Material: aluminium, aluminium alloy, galvanized steel, stainless steel, copper or brass.

Material: aluminium, aluminium alloy, galvanized steel, stainless steel, copper or brass.

Thickness: 1–5mm.

Thickness: 1–5mm.

Width: 0.8–1.5 m.

Width: 0.8–1.5 m.

Length: 2.25, 2.5, 3 m.

Length: 2.25, 2.5, 3 m.

Standard Size: 1.27 × 2.5, 1.5 × 2.25, 1.5 ×3 m.

Standard Size: 1.27 × 2.5, 1.5 × 2.25, 1.5 ×3 m.

Hole Diameter: 5–89 mm.

Hole Diameter: 5–89 mm.

Hole Arrangement Mode: straight, staggered.

Hole Arrangement Mode: straight, staggered.

Staggered Center: 0.125–1.875 mm.

Staggered Center: 0.125–1.875 mm.

Mesh Opening Area: 7% – 83%.

Mesh Opening Area: 7% – 83%.

Pattern Design: available.

Pattern Design: available.

Surface Treatment: standard,Anodized oxidation, galvanized, powder coating or PVDF

Surface Treatment: standard,Anodized oxidation, galvanized, powder coating or PVDF

Package: Galvanized Pallet+Plastic film+Waterproof paper,Wooden case + Sponge film or as customer’s request

Package: Galvanized Pallet+Plastic film+Waterproof paper,Wooden case + Sponge film or as customer’s request

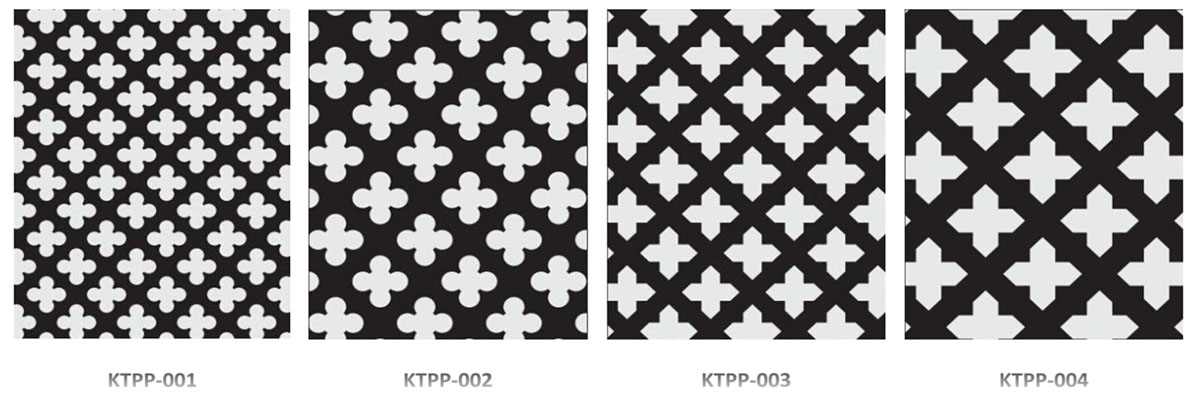

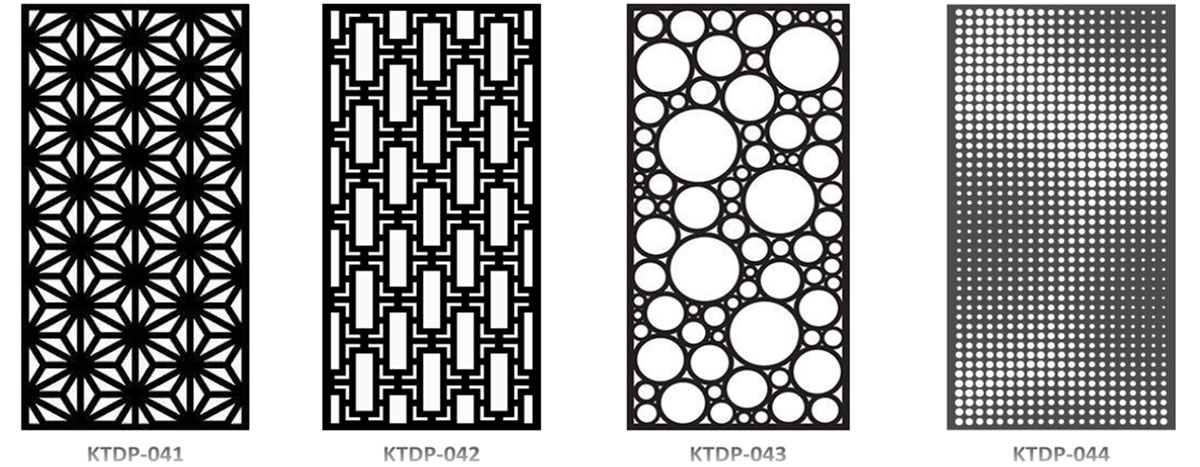

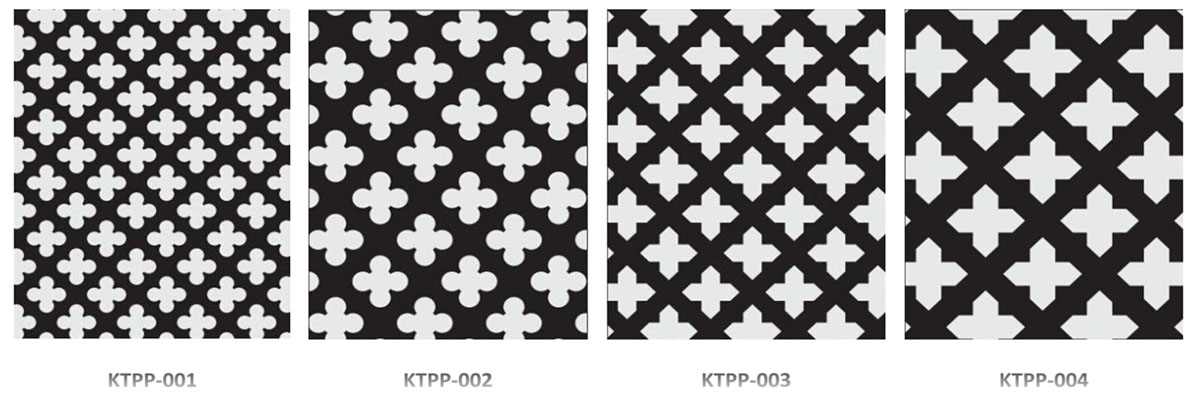

A variety of hole types are available

*Other special design also available,please feel free contact us for more details

MORE DESIGN PLEASE REFERENCE/DOWNLOAD  PERFORATED SHEET.pdf

PERFORATED SHEET.pdf

Application

Sheet Master: Automated loading and unloading

Sheet Master: Automated loading and unloading