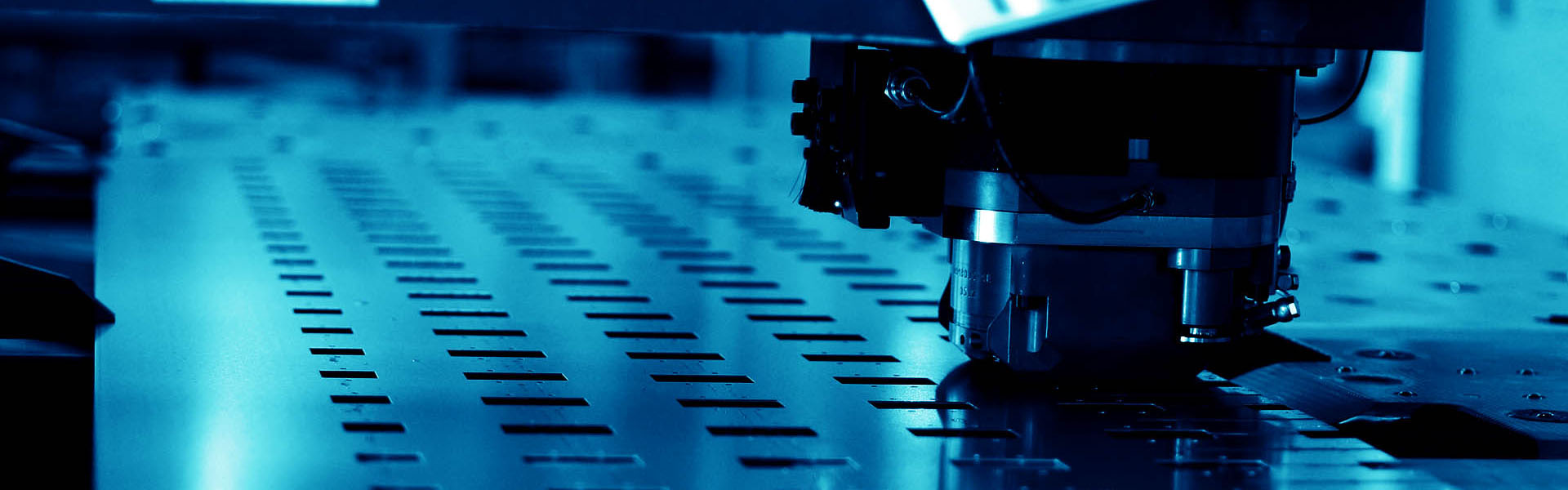

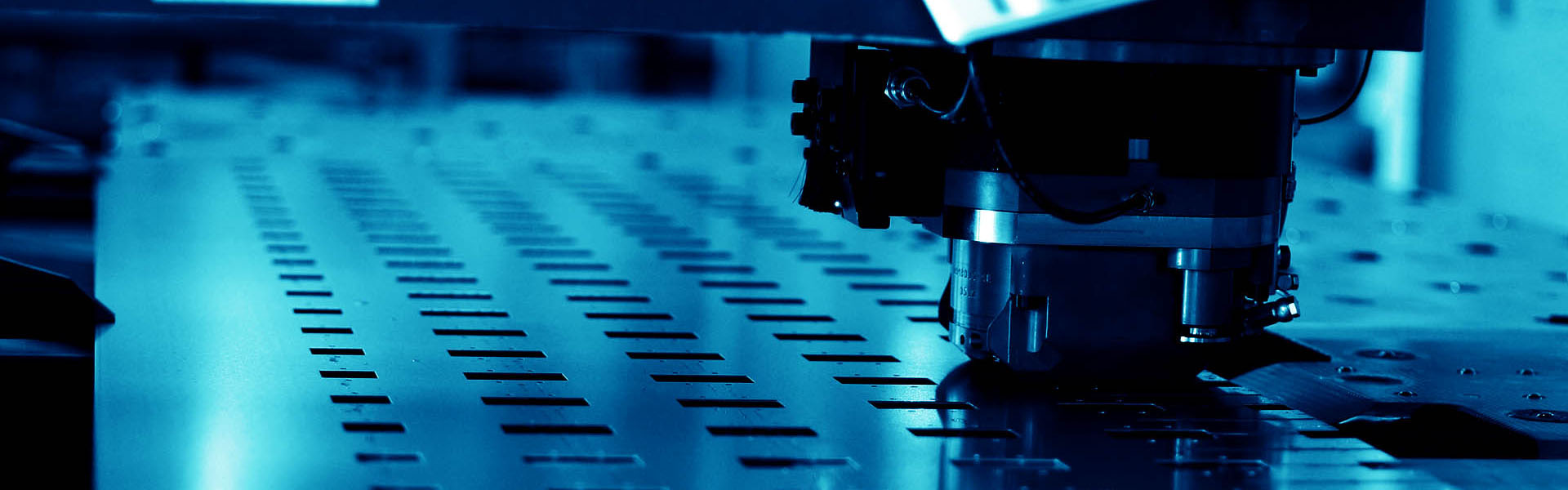

CNC punching perforated metal panels have precise hole sizes and various patterns available for choice. Mostly products can be applied widely in architectural ornament applications.

CNC punching perforated metal panels have precise hole sizes and various patterns available for choice. Mostly products can be applied widely in architectural ornament applications.

CNC punching perforated metal panels are referred to perforated metal sheets which are manufactured through computer numerically controlled punching process. As a manufacturer, we can CNC punch the architectural decorative panels from stainless steel, galvanized steel and aluminum as well as copper and brass. Simple shapes include square, round or hexagonal can be formed directly on the sheet. And complex shapes can be cut out by arranging many squares or rounded cuts around the perimeter.

High efficiency production.

High efficiency production.

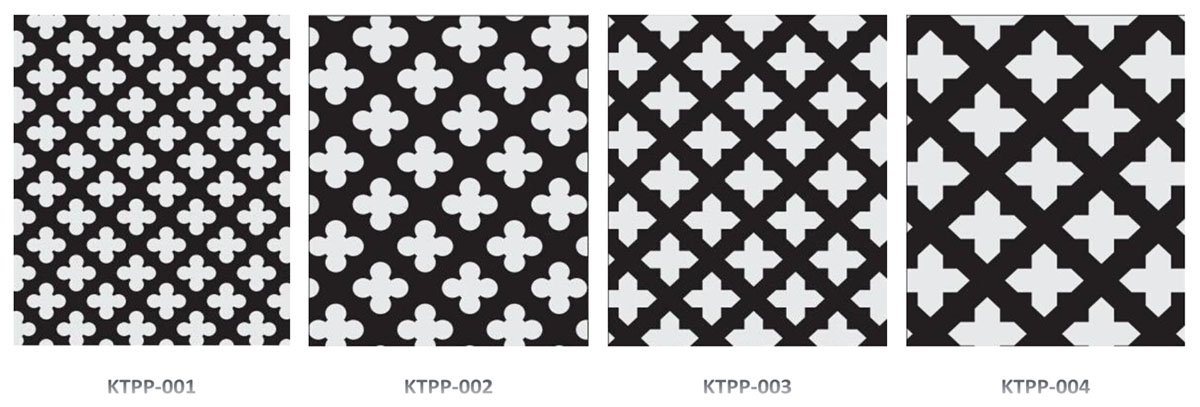

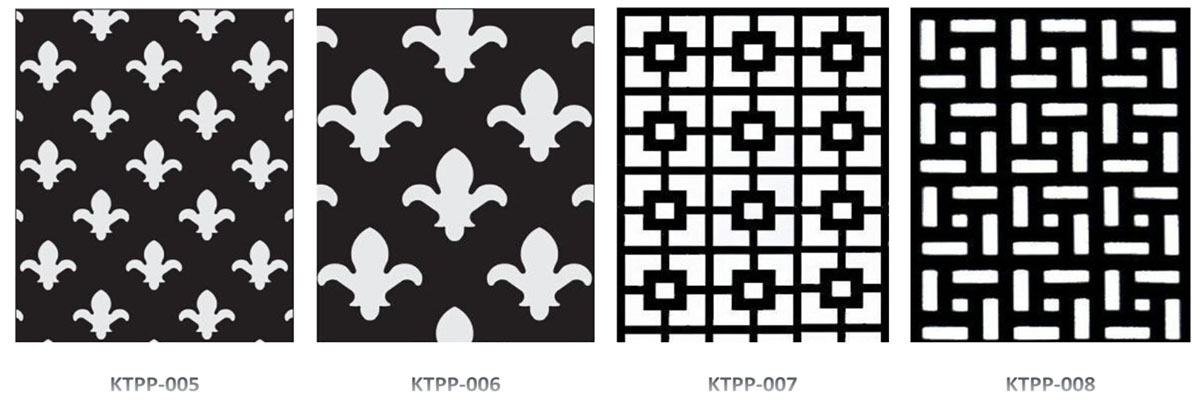

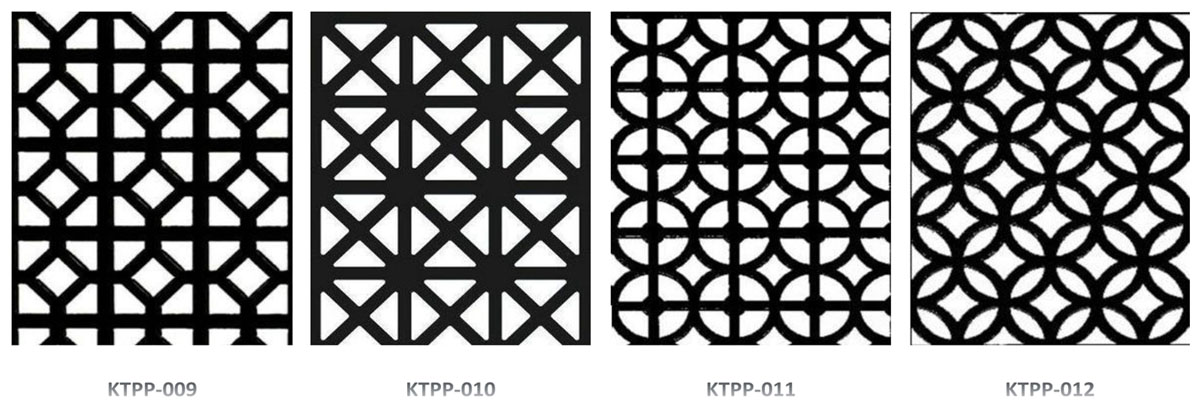

Various patterns, accurate hole size.

Various patterns, accurate hole size.

Increased throat deep and working area.

Increased throat deep and working area.

Naturally lightweight and high strength.

Naturally lightweight and high strength.

Optional metal plate thicknesses.

Optional metal plate thicknesses.

Can be painted, galvanized or polished.

Can be painted, galvanized or polished.

Material: aluminium, aluminium alloy, galvanized steel, stainless steel, copper or brass.

Material: aluminium, aluminium alloy, galvanized steel, stainless steel, copper or brass.

Thickness: 1–10 mm.

Thickness: 1–10 mm.

Width: 0.8–1.5 m.

Width: 0.8–1.5 m.

Length: 2.25, 2.5, 3 m.

Length: 2.25, 2.5, 3 m.

Standard Size: 1.27 × 2.5, 1.5 × 2.25, 1.5 ×3 m.

Standard Size: 1.27 × 2.5, 1.5 × 2.25, 1.5 ×3 m.

Hole Diameter: 5–89 mm.

Hole Diameter: 5–89 mm.

Hole Arrangement Mode: straight, staggered.

Hole Arrangement Mode: straight, staggered.

Staggered Center: 0.125–1.875 mm.

Staggered Center: 0.125–1.875 mm.

Mesh Opening Area: 7% – 83%.

Mesh Opening Area: 7% – 83%.

Pattern Design: available.

Pattern Design: available.

Surface Treatment: standard, anodic oxidation, galvanized, powder coating or fluorine carbon spraying.

Surface Treatment: standard, anodic oxidation, galvanized, powder coating or fluorine carbon spraying.

Package: Galvanized Pallet+Plastic film+Waterproof paper,Wooden case + Sponge film or as customer’s request

Package: Galvanized Pallet+Plastic film+Waterproof paper,Wooden case + Sponge film or as customer’s request

|  |  |  |  |

|  |  |  |  |

*Other special design also available,please feel free contact us for more details

MORE DESIGN PLEASE REFERENCE/DOWNLOAD ![]() PERFORATED SHEET.pdf

PERFORATED SHEET.pdf

Ceiling.

Curtain wall.

Cladding.

Security guard.

Window protection.

Screen & air diffuser.

Privacy separation.

Acoustics and soundproofing.

Louvre and ventilation.

Copyright © 2019 - KENTE MESH MANUFACTURE CO.,LIMITED 冀ICP备19031007号-1

links: 宏宇网业 饶阳县泰丰聚酯丝网有限公司 TAIFENG POLYESTER SCREEN