PROFESSIONAL FOR TRUST SINCERITY AND HONESTY FOR FUTURE

STRICT QUALITY CONTROL SYSTEM ENSURES THE QUALITY OF FINISHED PRODUCTS

We have established a complete set of quality control system. All workers must pass post assessment before taking up the position and produce according to international standards. Strict inspection runs through all production links to ensure all products are qualified before storing in the warehouse. We implement our quality control system from the following aspects.

| Characteristics | Detection Method | Detection Results |

| Hole Size (Thickness ≥ 3 mm) | ||

| Round hole at 60 ° stagger | ISO 7805-1:1984 GB/T 10613-2003 | 3.15 mm – 125 mm |

| Square hole | ISO 7805-1:1984 GB/T 10613-2003 | 3.15 mm – 125 mm |

| Tolerance on average size (Thickness ≥ 3 mm) | ||

| Round hole at 60 ° stagger | ISO 7805-1:1984 GB/T 10613-2003 | ±0.15 mm ~ ± 3 mm |

| Square hole | ISO 7805-1:1984 GB/T 10613-2003 | ±0.15 mm ~ ± 3 mm |

| Pitch Size (Thickness ≥ 3 mm) | ||

| Round hole at 60 ° stagger | ISO 7805-1:1984 GB/T 10613-2003 | 6.3 mm – 160 mm |

| Square hole | ISO 7805-1:1984 GB/T 10613-2003 | 6.3 mm – 160 mm |

| Tolerance on average size (Thickness ≥ 3 mm) | ||

| Round hole at 60 ° stagger | ISO 7805-1:1984 GB/T 10613-2003 | ±0.2 mm ~ ±2.9 mm |

| Square hole | ISO 7805-1:1984 GB/T 10613-2003 | ±0.2 mm ~ ±2.9 mm |

| Hole Size (Thickness < 3 mm) | ||

| Round hole | ISO 7805-2:1987 GB/T 10612-2003 | 0.5 mm – 13 mm |

| Square hole | ISO 7805-2:1987 GB/T 10612-2003 | 2.0 mm – 10 mm |

| Tolerance on average size (Thickness < 3 mm) | ||

| Round hole | ISO 7805-2:1987 GB/T 10612-2003 | ±0.1 mm ~ ± 0.35 mm |

| Square hole | ISO 7805-2:1987 GB/T 10612-2003 | ±0.2 mm ~ ± 0.35 mm |

| Pitch Size (Thickness < 3 mm) | 6.3 mm – 160 mm | |

| Round hole | ISO 7805-2:1987 GB/T 10612-2003 | 1.5 mm - 18mm |

| Square hole | ISO 7805-2:1987 GB/T 10612-2003 | 4.0 mm - 18 mm |

| Tolerance on average size (Thickness < 3 mm) | ||

| Round hole | ISO 7805-2:1987 GB/T 10612-2003 | ±0.05mm ~ ±0.5mm |

| Square hole | ISO 7805-2:1987 GB/T 10612-2003 | ±0.2mm ~ ±0.5mm |

| Tolerances on width and length (≤3mm-12.5mm) | ISO 10630_1994 GB/T 19360-2003 | ±0.8 mm ~ ± 12 mm |

| Tolerance on squareness (≤3mm-12.5mm) | ISO 10630_1994 GB/T 19360-2003 | ±0.75% - ±5% |

| Tolerance on flatness (≤0.7mm-12.5mm) | ISO 10630_1994 GB/T 19360-2003 | ±10 mm ~ ± 30 mm |

| Maximum height of burrs (≤0.6mm-12.5mm) | ISO 10630_1994 GB/T 19360-2003 | ±0.15 mm ~ ± 0.5 mm |

| Perforated opening size | ||

| Round Opening | ASTM E674-12 | 0.5 mm – 125.0 mm |

| Square Opening | ASTM E454-12 | 3.25 mm – 125.0 mm |

| Tolerance on openings | ||

| Round Opening | ASTM E674-12 | ±0.04 mm ~ ±2.5 mm |

| Square Opening | ASTM E454-12 | ±0.17 mm ~ ±2.5 mm |

| Tolerance on bars | ||

| Round Opening | ASTM E674-12 | ±0.06 mm ~ ±3.2 mm |

| Square Opening | ASTM E454-12 | ±0.20 mm ~ ±3.2 mm |

| Tolerance on thickness | ||

| Round Opening | ASTM E674-12 | ±0.18 mm ~ +1.00 mm/-0.25 mm |

| Square Opening | ASTM E454-12 | ±0.18 mm ~ +1.00 mm/-0.25 mm |

As we all know, skilled workers are big assets of manufacturing enterprises and a strong guarantee of smooth and efficient production. All workers in the plant must be trained for 1 or 2 months before taking up their position. Only those who passed the training test can mount guard.

Their duties include operating machines, observing machine running conditions and finished products conditions.

Opening Tolerance

Samples and products will be inspected according to international standard. All delivered products are in accordance with the standard tolerances.

The opening tolerances of our perforated metal sheet are compliance with the following standards.

Bar Tolerance

Tolerances on bars used in USA Standard Specification for Industrial Perforated Plate and Screens (round & square opening) shall comply with tables listed below.

The bar tolerances of our perforated metal sheet are compliance with the following standards.

Tolerance on Bar of Round Opening in Accordance with ASTM E674-12

Tolerance on Bar of Square Opening in Accordance with ASTM E454-12

Thickness Tolerance

Samples and products will be inspected according to the following standards. All delivered products are accord with the standard tolerances.

The thickness tolerances of our perforated metal sheet are compliance with the following standards.

Tolerance on Thickness of Round Opening in Accordance with ASTM E674-12

Tolerance on Thickness of Square Opening in Accordance with ASTM E454-12

Margin Tolerance

Margin width will confirm with our customers. And we will inspect margin based on the following standards.

Tolerance on width and length(Unit:mm)

Nominal Width or Length a1 or b1 Tolerance on a1 or b1 for nomimaml plate and thickness t t ≤ 3 3 < t ≤ 5 5 < t ≤ 10 10 < t ≤ 12.5 a1 or b1 ≤ 100 ±0.8 ±1.1 ±1.5 ±2 a1 > 100 or b1 ≤ 300 ±1.2 ±1.6 ±2 ±3 a1 > 300 or b1 ≤ 1000 ±2 ±2.5 ±3 ±4 a1 > 1000 or b1 ≤ 2000 ±3 ±4 ±5 ±6 a1 > 2000 or b1 ≤ 4000 ±4 ±6 ±8 ±10 a1 or b1 > 4000 ±5 ±8 ±10 ±12 Tolerance on Squareness in Accordance with GB/T 19360-2003 & ISO 10630 (Unit: mm)

Nominal Plate Thickness, t Tolerance on Squareness as A Percentage of a1 t ≤ 3 0.75 3 < t ≤ 5 1.5 5 < t ≤ 10 3 10 < t ≤ 12.5 5 Surface Flatness

All production will ongoing according to GB and ISO standard.

Twice inspection will be conducted during and after production.

The tolerances on the flatness of perforated metal plates,roller-levelled after perforation,apply for plates

with a maximum length of 2000mm

with margin ≤ t + 0.5p

Open area ranges from 20% to 40%

Tolerance on Flatness in Accordance with GB/T 19360-2003 & ISO 10630 (Unit: mm)

Nominal Width or Length a1 or b1 Tolerance on flatness for nomimal plate thickness t t ≤ 0.7 0.7 < t ≤ 1.2 1.2 < t ≤ 3 3 < t ≤ 5 5 < t ≤ 12.5 a1 or b1 ≤ 1200 20 18 15 12 10 a1 > 1200 or b1 ≤ 1500 28 22 18 16 14 a1 > 1500 or b1 ≤ 2000 30 25 20 16 14 Manufacturing Defects

We will inspect the samples and products according to the following standards to reduce the manufacturing defects.

In accordance with GB/T 19360-2003 & ISO 10630 standard, we will check if our products have manufacturing defects as listed below.

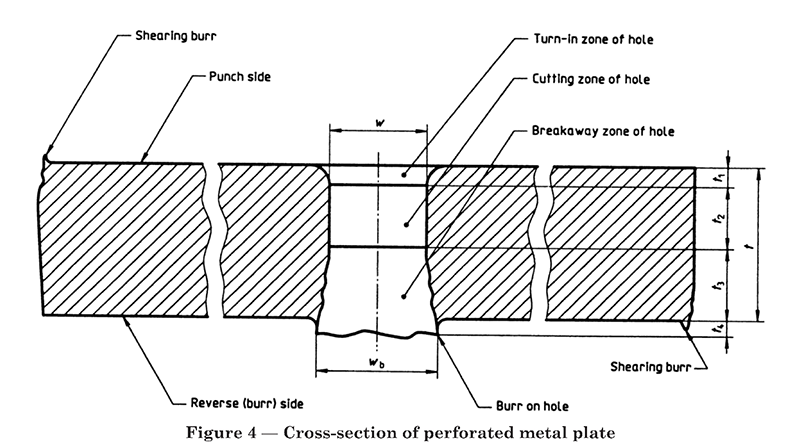

Breakaway on holes(see Figure 4)

When the punch has penetrated deeply into the metal plate from the punch side, material will begin to tear, or break away, mainly from the reverse side of the plate.

It is not possible to predict the precise shape and dimensions of the breakaway zone, but its height t 3 does not usually exceed two thirds of the plate thickness t. The width of the breakaway w b is roughly related to the plate thickness t and does not usually exceed the nominal hole size w by an amount of 0,15 t.

Burrs on holes and shearing burrs(see Figure 5)

Burrs will occur during both the perforating and the cutting (shearing) operations.

While burrs on holes occur on the reverse side of the plate only, shearing burrs may occur on either the punch side or the reverse side, depending on the manufacturing procedure adopted.

Not more than 10 % of the number of holes or 10 % of the length of a cut edge of a perforated metal plate shall have burr heights in excess of the values stated in below sheet.

Measure the burrs on holes with a depth micrometer and the shearing burrs with a vernier calliper.

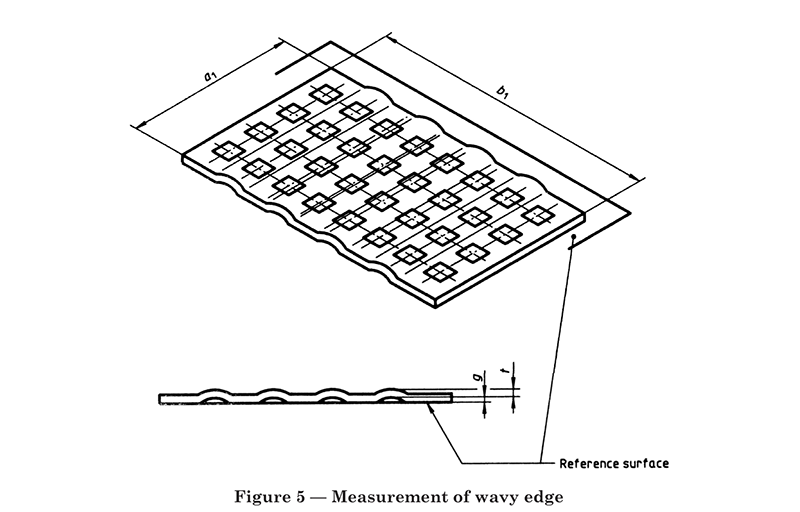

Wavy edge (see Figure 5)

Stresses during perforation can distort the plate and cause variations in flatness in the margin areas, producing a so called “wavy edge”, particularly if the margins on opposite sides are greater than the plate thickness t + 0,5 p. The maximum permissible deviation from the flatness of edges g shall be agreed before ordering.

Edge bow (camber) (see Figure 6)

Stresses during perforation and subsequent roller levelling processes can distort the plate, producing curving of the edges (edge bow/camber), particularly if the longitudinal margins e 1 and e 2 are unequal and parallel to the direction of perforation.

Edge bow is defined as the greatest deviation h of the edge from a straight line extending over the length of the concave side and shall be measured with the aid of a straightedge of sufficient length having a scale graduated in millimetres. The maximum permissible edge bow shall be agreed before ordering.

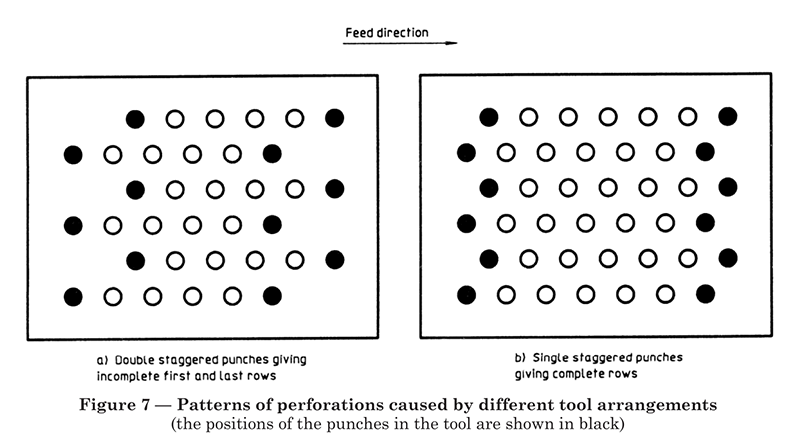

Missing holes (see Figure 7)

Punches may break during the perforation process and fail to perforate in certain positions. The number of holes missed for this reason should not exceed 5 % of the total number of holes in a perforated plate.

When a multitool punch is used, it may not be possible to complete the pattern of perforations. For example, to minimize tool damage, punches of diameter less than 5 mm are usually spaced wider apart than the pitches of the holes. This arrangement, however, unavoidably results in missing holes in one or more rows at both ends of the plate (incomplete rows).

| Nominal Pitch, p | Tolerance on Width of Margins, e, f |

| p ≤ 5, open area ≤ 25% | ±5 |

| p ≤ 5, open area > 25% | ±10 |

| 5 < p ≤ 20 | ±10 |

| 20 < p | ±0.5p |

Width and length refer to plates before perforating.

Skilled Workers and advanced equipment can guarantee the products within standard tolerances. The standard tolerances are listed in the table below(Refer ISO 10630 standard)

Squareness, refers cut perforated metal plates is quantified by the orthogonal projection of a transverse edge (plate width a1) onto a longitudinal edge (plate length b1).

The squareness of perforated metal sheet shall comply with GB/T 19360-2003 & ISO 10630 standard.

| Maximum height of burrs (Unit:mm) | |

| Nominal plate thickness, t | Maximum height of burr,t4 |

| t ≤ 0.6 | 0.15 |

| 0.6<t≤1.5 | 0.17 |

| 1.5<t≤3 | 0.2 |

| 3<t≤6 | 0.28 |

| 6<t≤10 | 0.5 |

| 10<t≤12.5 | 0.75 |

Other special design,we will inspect strictly in accordance with the drawings to ensure that each piece meets the customer's requirements.